Air Compressor

How to choose the best air compressor for my workshop?

The use of one or another type of air compressor will depend on the needs of the installation in terms of flow and pressure of the compressed air, it is also important to know the field of application of each type of compressor, to choose the most appropriate.

What kind of air compressor to choose:

Screw compressor

Screw compressor  Piston compressor

Piston compressorThe requirements of flow and compressed air pressure lead to choosing the power of the compressor, since each compressor is capable of guaranteeing a flow rate and a certain pressure with a different power.

To calculate the air flow you need to add the flow of every pneumatic tool to individual , which results in the maximum needs of air flow, and applying some coefficients to adapt the maximum theoretical consumption to the reality of each workshop, because not all the equipment works simultaneously.

We should not choose only for the price since cheap air compressors can cost us more in the long run.

Example:

To perform the calculation of the compressed air flow it is necessary to establish an average flow rate for each of the pneumatic tools (for example, 300 l / min.), As well as how many people will use the tools at the same time .

To obtain the total amount, simply multiply the average consumption , ie 300 liters / minute, by the number of workshop workers (imagine that everyone is working at the same time). Finally, to the total obtained, we must apply a coefficient of simultaneity (being 1, to be connected all at the same time, so we will take a value always less than 1).

Body / mechanical workshop | |

Number of workers | 5 |

Total expected flow | 300 x 5 = 1.500 l/min |

Simultaneity coefficient | 0,6 |

Total flow = 900 l/min |

Once we have an approximate calculation of air consumption and pressure, we can determine the power of the compressor. The following table can guide you about the power of the air compressor; However, before deciding on one or the other, you can contact us and we will advise you.

| Power (HP) | 3 | 5.5 | 10 | 15 | 20 |

| Flow (L/MIN) | 300 | 720 | 860 | 1430 | 1900 |

| Pressure (BAR) | 9 | 10 | 10 | 10 | 10 |

COMPRESSORS | SPIRAL | PISTON | SCREW | ||

SILENTKROLL 3/150/360-10 | AB 200-360 | AB 300-550 | SSA 410/300 | PKL C 3/10 200D | |

SOUND LEVEL dB(A) | 30±5 | 74 | 75 | 68 | 74 |

COMPRESSED AIR EFFECTIVE l/min | 360 | 252 * | 396 * | 288 * | 220 |

EFFECTIVE AIR PER HOUR OF OPERATION l/h | 21.600 | 9.072 | 14.256 | 10.368 | 13.200 |

WORK % | 100 | 60 | 60 | 60 | 100 |

COMPRESSED AIR TEMPERATURE °C | 20 + T.A | 60 + T.A. | 60 + T.A. | 60 + T.A. | 30 + T.A. |

MAINTENANCE | Once a year / every 1000 hours | Every 200 hours | Every 200 hours | Every 200 hours | Once a year / every 1000 hours |

POWER kw | 2,2 | 2,2 | 4 | 2,2 | 2,2 |

COMPRESSORS | SPIRAL | PISTON | SCREW | ||

SILENTKROLL-M 6/670-10 | AB 300-550F | NEW SILVER 5,5 | CRS 5,5* | CRS 7,5 | |

SOUND LEVEL dB(A) | 30±5 | 75 | 65 | 66 | 67 |

COMPRESSED AIR EFFECTIVE l/min | 670 | 396 * | 450 | 420 | 660 |

AIRE EFECTIVO POR HORA DE FUNC. l/h | 40.200 | 14.256 | 27.000 | 25.200 | 39.600 |

WORK % | 100 | 60 | 100 | 100 | 100 |

COMPRESSED AIR TEMPERATURE °C | 20 + T.A | 60 + T.A. | 30 + T.A. | 30 + T.A. | 30 + T.A. |

MAINTENANCE | Once a year / every 1000 hours | Every 200 hours | Once a year / every 1000 hours | Once a year / every 1000 hours | Once a year / every 1000 hours |

POWER kw | 4,5 # | 4 | 4 | 4 | 5,5 |

T.A.= ROOM TEMPERATURE

* Measured at room temperature: 22.5 °C.

# Despite being slightly higher electricity consumption, producing more air, in the long run it is more economical.

COMPRESSORS | SPIRAL | PISTON | SCREW | |

SILENTKROLL-M 10/1200-10 | LOTAN 100 | NEW SILVER 10 | CRS 10 | |

SOUND LEVEL dB(A) | 45±5 | 71 | 67 | 67 |

COMPRESSED AIR EFFECTIVE l/min | 1.200 | 871,2 * | 860 | 970 |

AIRE EFECTIVO POR HORA DE FUNC. l/h | 72.000 | 31.363,2 | 51.600 | 58.200 |

WORK % | 100 | 60 | 100 | 100 |

COMPRESSED AIR TEMPERATURE °C | 20 + T.A | 60 + T.A. | 30 + T.A. | 30 + T.A. |

MAINTENANCE | Once a year / every 1000 hours | Every 200 hours | Once a year / every 1000 hours | Once a year / every 1000 hours |

POWER kw | 7,5 | 7,5 | 7,5 | 7,5 |

COMPRESSORS | SPIRAL | SCREW |

SILENTKROLL-M 15/1000-15 | CRS 15 | |

SOUND LEVEL dB(A) | 38±5 | 68 |

COMPRESSED AIR EFFECTIVE l/min | 1.000 ## | 1.130 |

AIRE EFECTIVO POR HORA DE FUNC. l/h | 60.000 ### | 67.800 |

WORK % | 100 | 100 |

COMPRESSED AIR TEMPERATURE °C | 20 + T.A | 30 + T.A. |

MAINTENANCE | Once a year / every 1000 hours | Once a year / every 1000 hours |

POWER kw | 11 | 11 |

T.A.= ROOM TEMPERATURE

* Measured at room temperature: 22.5 °C.

## The effective air obtained in the Silentkroll is 1000 l / min. at 15 bars, while the other is 1130 l / min. at 13 bars.

### The effective air per hour of operation is 60,000 l / h at 15 bars, while the other is 67,800 l / h but at 13 bars.

Spiral scroll air compressors

What is a scroll air compressor?

The scroll compressor is a positive displacement compressor . It is not a well-known equipment, but it has a typical application in oil-free applications.

The spiral compressor has an orbital displacement. The compression is done by volume reduction. The compressor assembly consists of two spiral-shaped rotors; one of them is fixed in the housing and the other is mobile, driven by the motor. They are mounted with a phase shift of 180º, which allows smaller air chambers to be created in their movement.

Refrigerated type dryers

Rotary Screw Air Compressor

Do you know what are the advantages of this type of compressor?

Best running

A screw compressor uses rotating elements smaller and better capacity, thus preventing vibration and friction cause the pistons and thus achieving greater mechanical efficiency.

Higher air output by HP

Thanks to their greater efficiency, the screw compressor produces more air by HP. Generally, a piston compressor produces 3 to 3.5 cubic feet minute / HP. A screw compressor produces cubic feet 4 to 5 minutes / HP., Exceeding the compressor piston 30%.

Major work period under load.

Because of increased heat in the compressor piston, the working period under load is 50% -60%, with a maximum of 80%. Screw compressors are designed to operate with a period of low work load of 100%, ie continuously.

Durability

This is thanks to their greater efficiency, functioning more chilled and better balance. The screw compressor has a longer life, generally twice the compressor piston.

Screw Compressors | ||||||||||

Model | Volt/Hz | LT | l/min | HP | ||||||

CAT-100 | 230/50/1 | 90 | 300 | 3.0 | ||||||

CATS-300 | 400/50/3 | 270 | 720 | 7.5 | ||||||

CATS-500/7,5 | 400/50/3 | 500 | 720 | 7.5 | ||||||

CATS-500/10 | 400/50/3 | 500 | 860 | 10 | ||||||

CATS-500/15 | 400/50/3 | 500 | 1430 | 15 | ||||||

CATS-500/20 | 400/50/3 | 500 | 1900 | 20 | ||||||

BOILER SCREW COMPRESSORS | ||||||||||

Model | bar | HP | ||||||||

New silver 7,5 | 10 | 7.5 | ||||||||

New silver 10 | 10 | 10 | ||||||||

New silver 20 | 10 | 20 | ||||||||

Piston Air Compressor

Do you know what are the advantages of this type of compressor?

Long duration

The materials used in the manufacture of piston compressors must be of high quality and high resistance to friction and wear.

Variable compression capacity

Depending on the number of cylinders, the compressibility can increase or decrease, depending on the process needs.

Adaptable

Piston compressors can be adapted to the type of use and industrial process for which required.

PISTON COMPRESSOR SOUNDPROOF | |||||||||||

Model | Volt/Hz | LT | l/min | HP | |||||||

CAI-200 | 230/50/1 | 200 | 400 | 3 | |||||||

CAI-300 | 400/50/3 | 270 | 777 | 7.5 | |||||||

CAI-500 | 400/50/3 | 500 | 777 | 7.5 | |||||||

PISTON COMPRESSORS | |||||||||||

Model | Volt/Hz | LT | l/min | HP | |||||||

CA-50 | 230/50/1 | 50 | 338 | 2 | |||||||

CA-100 | 230/50/1 | 100 | 338 | 3 | |||||||

CA-200 | 230/50/1 | 200 | 360 | 3 | |||||||

CA-300 | 400/50/3 | 270 | 550 | 5.5 | |||||||

CA-300B | 400/50/3 | 270 | 600 | 5.5 | |||||||

CA-500 | 400/50/3 | 500 | 830 | 7.5 | |||||||

CA-500T(*) | 400/50/3 | 500 | 1280 | 10 | |||||||

(*) It includes box star-delta start

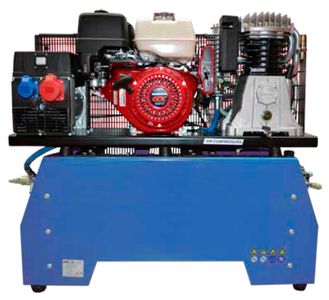

Gasoline Air Compressor

With these versatile air compressors driven by gasoline engine will be totally independent of any power source and compressed air available in all circumstances.

Why use a piston compressor with a petrol engine?

- Independent external energy sources.

- A powerful engine that supplies air and electricity.

- Motor gasoline Super muted.

- Low fuel consumption.

- Easy to move.

- Low noise level.

- Easy maintenance.

Air compressor THUNDER 130/5EM

- Power: 13 hp

- Fuel tank capacity: 50 liters

- Maximum pressure: 14 bar

- Intake air flow: 900 l / min

Air compressor THUNDER 130/7ET

- Power: 13 hp

- Fuel tank capacity: 50 liters

- Maximum pressure: 14 bar

- Intake air flow: 900 l / min

1 post lift

1 post lift 2 post car lifts

2 post car lifts 4 post lifts

4 post lifts Scissor lift

Scissor lift Parking Lifts

Parking Lifts Motorcycle lifts

Motorcycle lifts Rubber lift pads

Rubber lift pads Workbenches and Tool panels

Workbenches and Tool panels Tool Chests

Tool Chests Tool Cabinets

Tool Cabinets Impact Wrenches

Impact Wrenches Electric generators

Electric generators Ultrasonic cleaning machine

Ultrasonic cleaning machine Motorcycle Stands

Motorcycle Stands Industrial Vacuum

Industrial Vacuum Scroll air compressors

Scroll air compressors Rotary Screw Air Compressor

Rotary Screw Air Compressor Piston Air Compressor

Piston Air Compressor Car tire changers

Car tire changers Truck Tire Changers

Truck Tire Changers Car Wheel Balancers

Car Wheel Balancers Truck Wheel Balancers

Truck Wheel Balancers Wheel Weights

Wheel Weights Plasma Cutters

Plasma Cutters MIG Welding

MIG Welding TIG Welding

TIG Welding Stick Welding (SMAW)

Stick Welding (SMAW) Spot Welding

Spot Welding Hydraulic Press

Hydraulic Press Folding Engine Hoist

Folding Engine Hoist Nitrogen Generator

Nitrogen Generator Charger & Starters

Charger & Starters Hydraulic Floor Jacks

Hydraulic Floor Jacks Pneumatic hydraulic jacks

Pneumatic hydraulic jacks Air Hose Reel

Air Hose Reel Lubrication Equipment

Lubrication Equipment  Recharge A/C Machines

Recharge A/C Machines Car diagnostic tool

Car diagnostic tool Tire vulcanizing machine

Tire vulcanizing machine Adhesives & Glues

Adhesives & Glues